Adding Robots in Workspace

As more companies are going into Industrial 4.0 due to the demanding of supply coming from global and regional market, automation and data transfer in the manufacturing industry is essential.

Author: Ho Xiu Ting  Date: 7th September 2021

Date: 7th September 2021

![]()

![]()

Considering that the aging population is increasing worldwide for the next 20 years, lacking manpower in all industries is a problem for society. Meanwhile, when most of the millennials (aged 23 ~ 38 years old) are highly educated, they are unwilling to take up jobs that are repetitive and exhausting. Therefore, automation is introduced to the workplace, it enhances the rate of productivity and greatly reduces mistakes caused by human error during the repetitive process.

The digitalization of big data is the element factor that interconnects all machines together. The cloud is responsible to gather information and foresee any possible errors that might require attention which allows the employees to get ready in bad circumstances. Besides connecting machines together, digitalization enables information to be shared between departments. Such arrangement prevents miscommunication, real-time update is available if one of the parties modified the data. Consequently, executing industry 4.0 values allow companies to obtain better control, better visibility, and understand every aspect of the machines and management.

SWOT Analysis

Strength

- Enhanced the productivity - Reduced human error - Increase the employment rate in the IT and engineer sector - Technicians can make use of the time for a more efficient process - Available for real-time data - Planning in advance for various circumstances - Allowing companies to adapt in this competitive environment

Weaknesses

- High investment when building industry 4.0 - Require highly educated professionals to access - Lack of clarity of knowledge of big data - Rely greatly on technology

Opportunities

- Improved job opportunities - Self-optimization - Expansion to new market

Threats

- Reduced the unemployment rate of unskilled workers - Possibility that the data might be misused - Vulnerability to data loss

Although implementing robots into the workspace brings benefits, people are reluctant to accept the fact that they are being replaced by the robots. But the truth about implementing robots into the workforce is to improve the standard for the employees to utilize the remaining time for something more efficient.

Expedite the Process

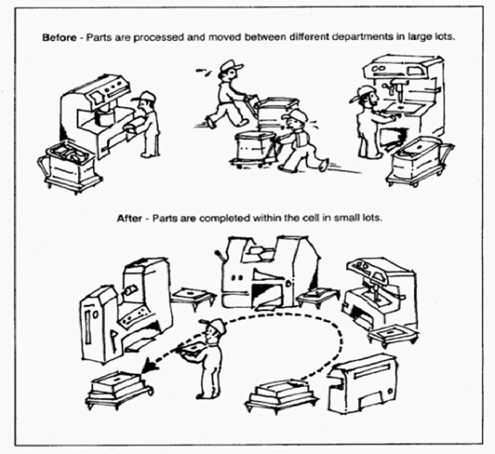

As industrial robots can work 24 hours without supervision, the completion of parts produced increased exponentially. Data of the robot can be projected where engineers or technicians is able to read and edit the process. Further improvements are made after determining the complete cycle time of a process to compare with the database. Constructing an automated throughput validation for speed model to create Unit Per Hour (UPH) could help to allocate losses so compensation can be done.

The factory can run on its own after the set-up is completed. Technicians are there to supervise multiple machines at the same time instead of focusing on just one machine previously. In such cases, people are utilizing their time to generate a more efficient process for productivity while the robots are serving their purposes.

Type of Robots

These are the robotics brands that we are representing. To understand which type of robot is suitable for your application, do refer to the capabilities described below.

Articulated Robots

Industrial Robots

It is programmed in such a way that no human interaction is needed during the whole process of the logistics chain. Industrial robots are often used in application that requires high precision, speed, and endurance. Industrial robots are mostly operated inside a safety cage due to the high velocity to improve workers safety and efficiency. Normally, it is used to replace human that carry out hazardous actions that cause harm to them if mistakes are irreversible.

(a) Mecademic - Meca500 (b) Shibaura Machine

Collaborative Robots

The inbuild force-torque sensor at the motor allows collaborative robots to have a safe interaction in the common workplace. They are designed in such a way to stop instantly after human contact with them. A collaborative robot is programmed to either stop the entire process and start from the initial phase, or it can set to resume the program by activating some buttons or motions. Since these robots have safety features, they are not required to be placed in a safety cage when operating.

(a) Rethink Robotics - Sawyer

Cartesian Robots

It is a type of industrial robot that perform in linear motion. The three sliding joints resemble to wrist up-down, in-out, and back-forth. Actuators are stacked on top of each other to simulate the X-Y motion. Multiple configurations of Cartesian Robots are built to satisfy client’s application needs.

(a) Hyulim Robot (b) Shibaura Machine

SCADA Robots

Comparing with Cartesian Robots, it is more expensive because of the controlling software that involves inverse kinematics for linear position often know as the teaching pendant. The layout of the SCADA robot allows the arm to fold and retract to avoid obstacles or transferring components from one location to another.

(a) Shibaura Machine (b) Hyulim Robot – DSA Series

Delta Robots

Unlike other types of robots mentioned, Delta Robot restricts movement of the platform to pure translation without any rotation. To enable the robots in the production line to move at a high-speed, actuators are mounted at the base to make the structure lighter.

(a) Atom Robotics – D3P Series

Do email us if you wish to consult or design a system using any of the robots mentioned above. For more information, do visit our website for the products or contact us if you are interested.

Reference

1. Integrate TRIZ into cellular manufacturing to improve productivity. Dr. John X. Wang (2015, May 20). https://drjohnxwang.wordpress.com/integrate-triz-into-cellular-manufacturing-to-improve-productivity/. 2. Smids, J., Nyholm, S., & Berkers, H. (2019, November 1). Robots in the workplace: A threat to-or opportunity for-meaningful work? Philosophy & Technology. https://link.springer.com/article/10.1007/s13347-019-00377-4#Sec15. 3. Yu, Z. (2019, April 5). Industry 4.0 - how does it benefit the smes? InvoiceInterchange. https://www.invoiceinterchange.com/industry-4-0-what-is-it-and-how-does-it-benefit-the-smes/.